Horizontal Stabilizer Start

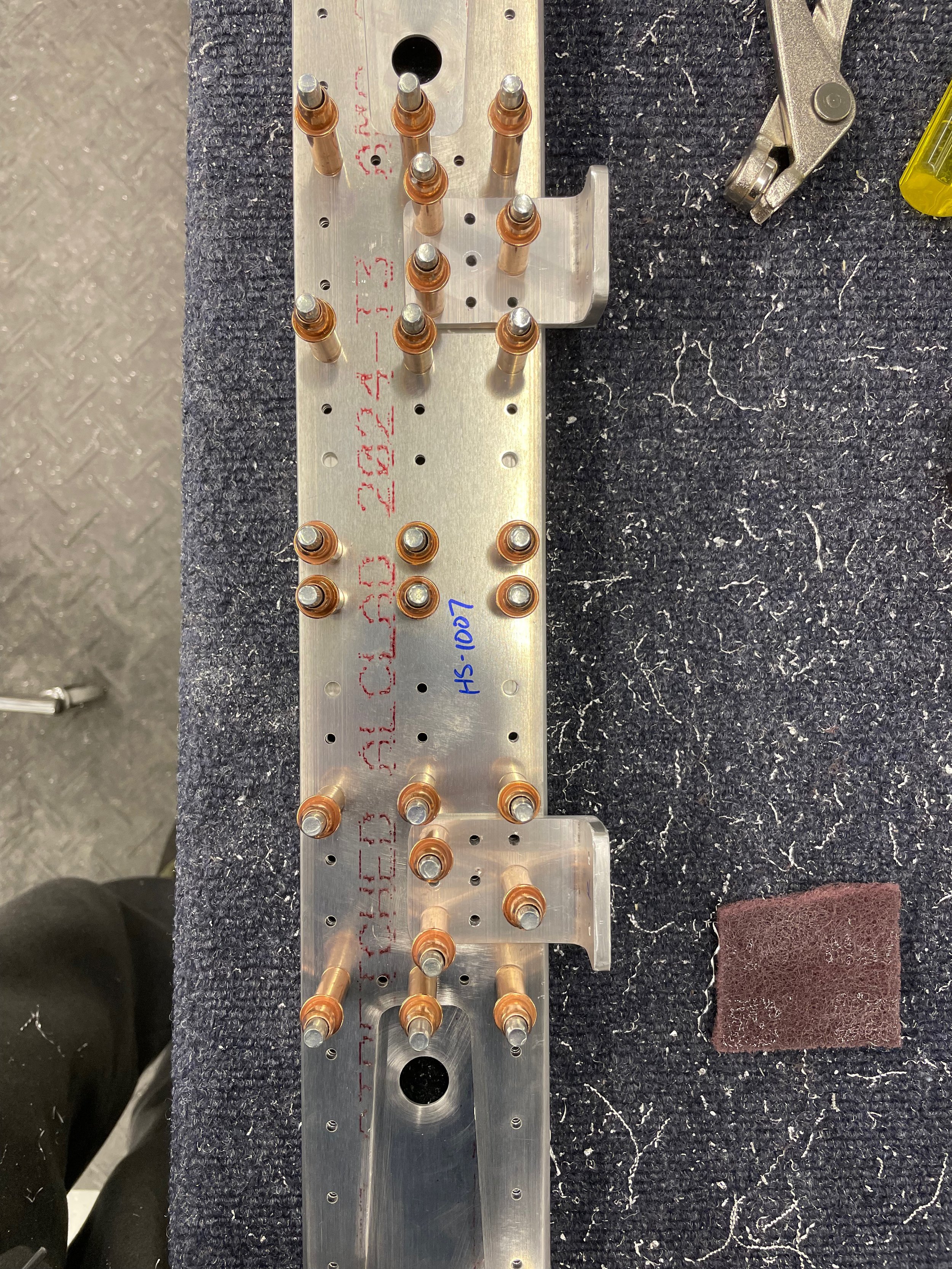

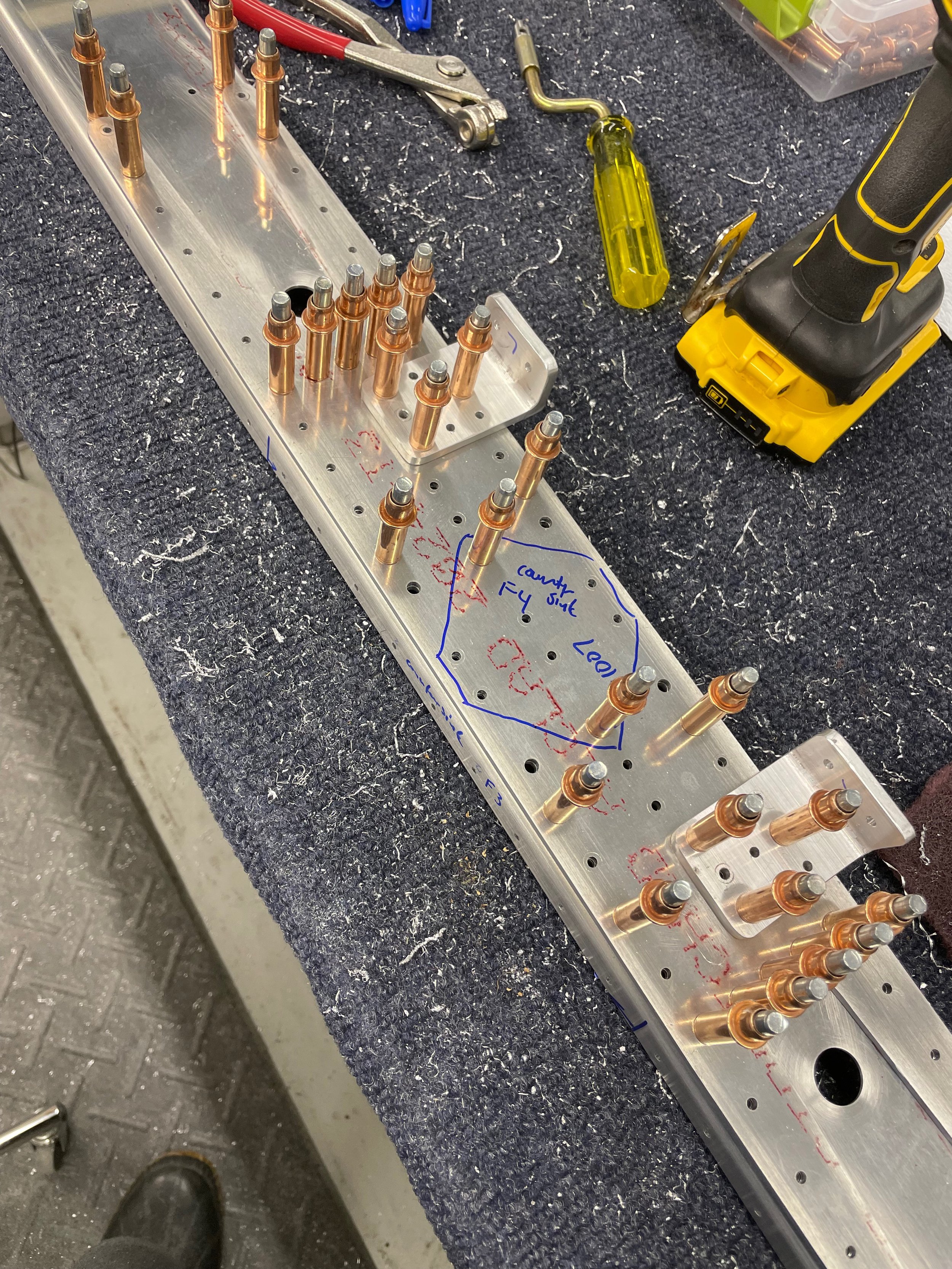

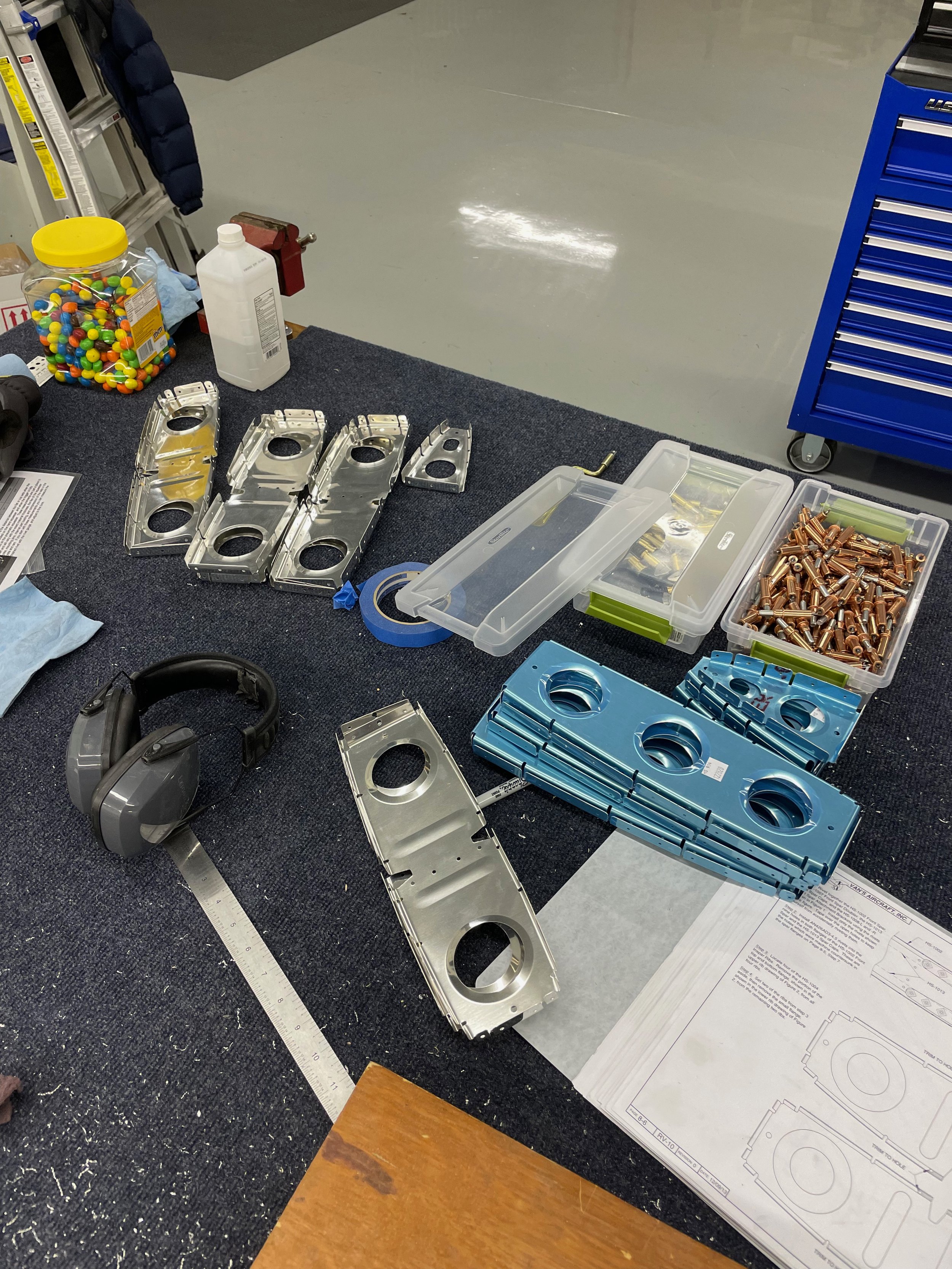

While waiting for the tank sealant to arrive to continue work on the rudder, I started preparing material for the horizontal stabilizer. This involved a whole day’s work cleaning up the edges on the biggest spars to-date. The long edges and lightening wholes were all tackled with a 1/4” die grinder fitted with a 1” 3M cut/polish wheel. The slowest part was allowing my air compressor to keep up and not stress its duty cycle. Then there’s trimming ribs and prepping ribs.

I’ve tried several different ways of getting the the spaces in between the rib flanges. I’ve done with cutting a wedge off of 3M wheel and putting it on a Dremel. This just burns through 3M wheel pieces. My go-to now is simple sand paper wrapped around a craft stick. I got a box of a billion small craft sticks for $1 in anticipation of needing to mix primer, epoxies and tank sealant.

I’ve noticed the nose ribs fit a lot easier into the horizontal stabilizer skins than the vertical stabilizer.

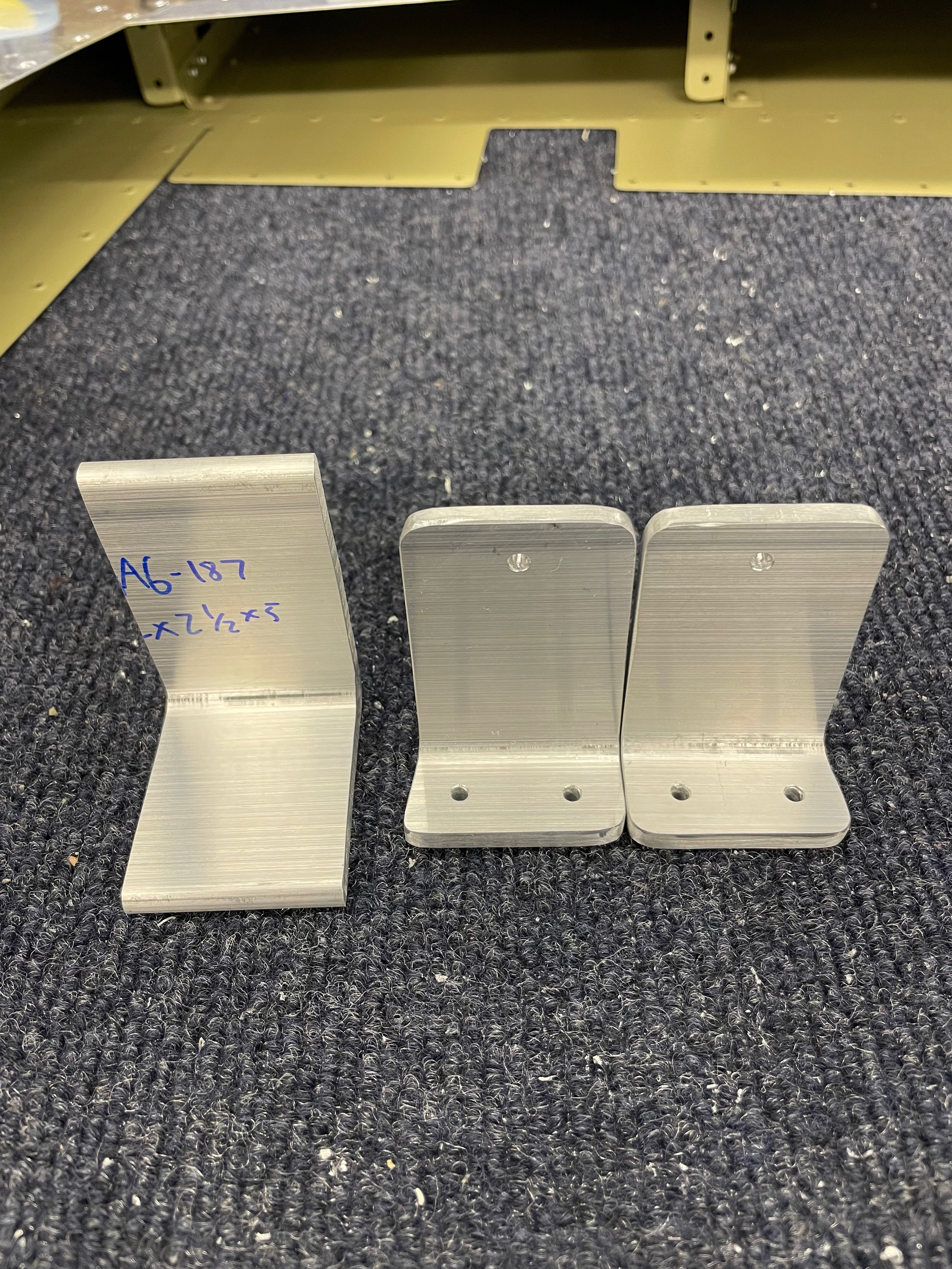

By far the most fun I’ve had so far is fabricating the front spar attach brackets. They start as a single piece of angle aluminum. Cut them into 2 pieces. then cut them to size. Then they are drilled and contoured. It’s a little difficult to see from the picture but the outside edges are not square, there is a taper to them. It’s so satisfying “machining” a raw piece of metal into an airplane part.

I know it’s early but I appreciate the balance of pre-fabrication and precise placement of holes done by Van’s and the little fabrication projects left to the builder.